Brodie MacGruer

Wind Turbine Technician at RES

How I got here

When I was growing up, I was always looking at following my dad into oil and gas, going offshore. But then I saw renewables coming up and thought that could be interesting.

To be fair, I didn't do that well at school. A lot of that was because of COVID and my first set of exams were cancelled. My favourite subjects were construction, tech, geography, engineering science. I was always wanting to go down the engineering route, but ideally something more practical.

After school, I went to Edinburgh College for a year to get some more qualifications in engineering. Then I came back up to Aberdeenshire and did a two-year course at NESCOL, which was specifically for wind turbine technicians. It was accredited by the ECITB.

The thing that made the difference was what I did in my holidays. I worked for J&S Subsea, got about six months of experience over my time at college. I got that through a friend who worked there - I just went and spoke to their workshop manager, asked if they had any work for me, even as a trainee. They took me on.

When I finished the course, I applied to RES and got the job. J&S actually offered me a role too, but I'd been wanting to get into turbines from the start, so I went with RES.

What I actually do day-to-day

I cover two wind farm sites in Aberdeenshire - one near Stonehaven and one between Insch and Huntly. There are four of us technicians covering both sites, and we rotate which one we're at each week. We work in teams of two.

On a general day, we show up at site and check the SCADA system. That shows us the condition of every turbine - if there are any faults, we can see what they are. We find the right procedure, then go out and see what's wrong. Sometimes it's just resetting it, sometimes it's proper fault finding and repair.

If all the turbines are running fine, we work through a fault list of minor jobs. During servicing windows, we'll be doing scheduled maintenance - greasing, oil changes, tolerance checks, that sort of thing.

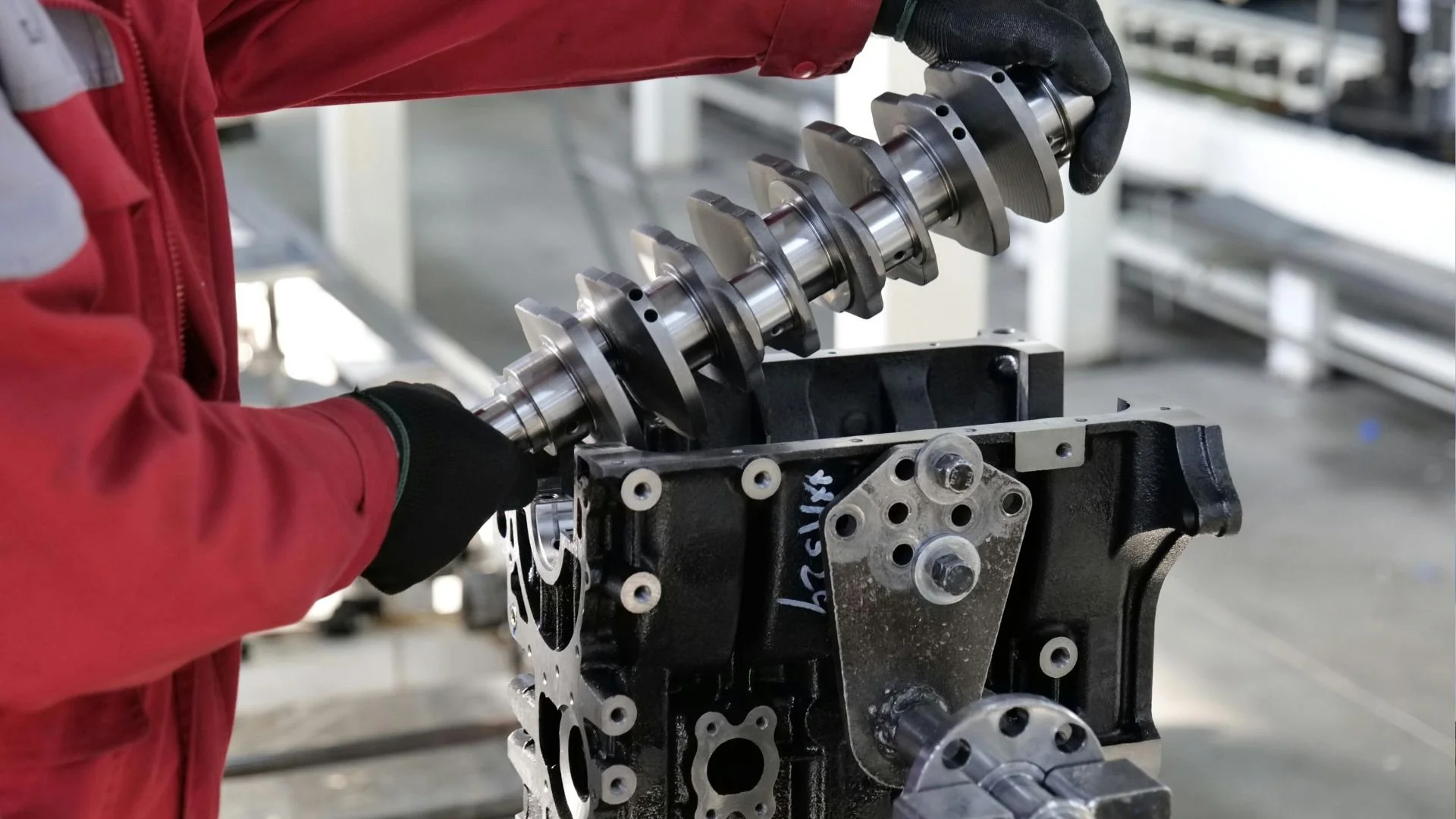

The repair work can be quite involved. Right now some of the lads are stripping down a generator to replace a damaged slip ring. A lot of it's broken down into smaller systems like the generator, gearbox, bearings and shafts. If you can work on a car, you can work on a turbine, more or less.

The really big stuff - changing out blades, gearboxes, whole generators - that gets done by a specialist major components team with cranes. We'd be part of that job, but not leading it.

What I enjoy about it

Getting to be outdoors. I would not like to be stuck in an office all day - that's not for me.

Being hands-on. When I was at college, whenever we were in the workshop I really enjoyed it. When we were in the classroom, the clock was just ticking by, couldn't go quick enough. We still have plenty of reports to do in this job, but at least we get the break to go out and do practical work.

And the industry itself - wind energy covers everything I was interested in. Being hands-on, being outdoors. The thought of it always looked like a good job to me, and now I'm doing it.

What you learn on the job

You've got to have a good understanding of each component - what it does, how it affects something else. You need to be inquisitive about what you're doing and why. I've always gone about it thinking if I don't understand it, I won't get the whole idea of how to do it.

Safety is the main thing. At RES, the motto is 'don't risk it'. If it's not safe to do the job, don't do it. You have to have pride in your work - there's no point doing a sloppy job and just getting it done as quick as you can. You need to do it in a way you'd be happy with if it was your own machine.

Working as a team is important too. Up a turbine, you're always a minimum group of two. It's better having two folk thinking about it, two folk working on it. One person could easily miss something or make a mistake and not realise.

My advice

Put it simply: don't wait for it to come to you. You've got to get out there.

I've seen lots of people who have plenty of qualifications that haven't managed to get jobs as they don't put themselves out there. And the ones who have managed to get jobs are the ones who went out, reached out to companies. From when I started the ECITB course, I was already reaching out trying to get my foot in the door.

It's all good knowing the theory, which you do need, but if you also have experience that puts you miles ahead of everyone else.

I'm 20 now and I'm happy where I am. There's no point rushing to the next thing. I'd like to get into offshore wind eventually, but right now I'm in a good team, getting the chance to learn, getting taught properly. That's worth more than jumping somewhere else too soon.