Thomas Hart

Control and Protection Engineer

at Siemens Energy

How I got here

I've always been interested in science stuff. I did Maths, Physics, and Biology for my A-levels, plus Further Maths in my first year. You don't need Further Maths or Biology for this role; it's mainly just Maths and Physics. They're not too fussy about what the other science is.

To be honest, I wanted to do aerospace before this. That was the actual dream. But when the Siemens opportunity came up, I had a choice between their degree apprenticeship or going to Northumbria Uni.

The thing that made me pick the degree apprenticeship over university was simple: I didn't want 60 grand worth of debt. That was like 100% the reason.

I got invited to interview and had about a week to prepare. I just researched the company, researched what they do, tried to get as much information as I could. The application process is competitive - they get about 200 people applying for engineering roles. You go through a paper sift, then group interaction sessions to see how you work with people, then you'll probably be given an interview or presentation. I had to do a 10-minute presentation and then an interview afterwards.

What I actually do day-to-day

I come in and do about two hours of uni work in the morning. Then my mentor comes in and I'll get some work from him. It'll normally be designing a wiring diagram or creating a Word document with specifications for a project, or working on an Excel sheet. I'll work on that until probably 2 or 3 o'clock, and then I'll finish off with a bit more uni work afterwards.

What I'm actually doing is working on substations. You've got a substation, and then you've got the protections to ensure that it doesn't turn off if there's a fault. My job is designing the power source for those protections, so it's the DC current behind those. I'm designing the diagrams on how it's laid out, how it works, the specifications of it, and also what components are part of that.

The primary engineers design the substation and how the buildings are laid out, how the actual equipment's laid out. Then the secondary engineers, that's us, we do the underlying parts that keep it running. We're ensuring that those building blocks function correctly.

Most of it's on the computer. I'll get a list of all the components for every protection that we have. I have to work out which ones actually need power to them, and which ones are just passive components that don't really need power. Then I put that into another Excel sheet.

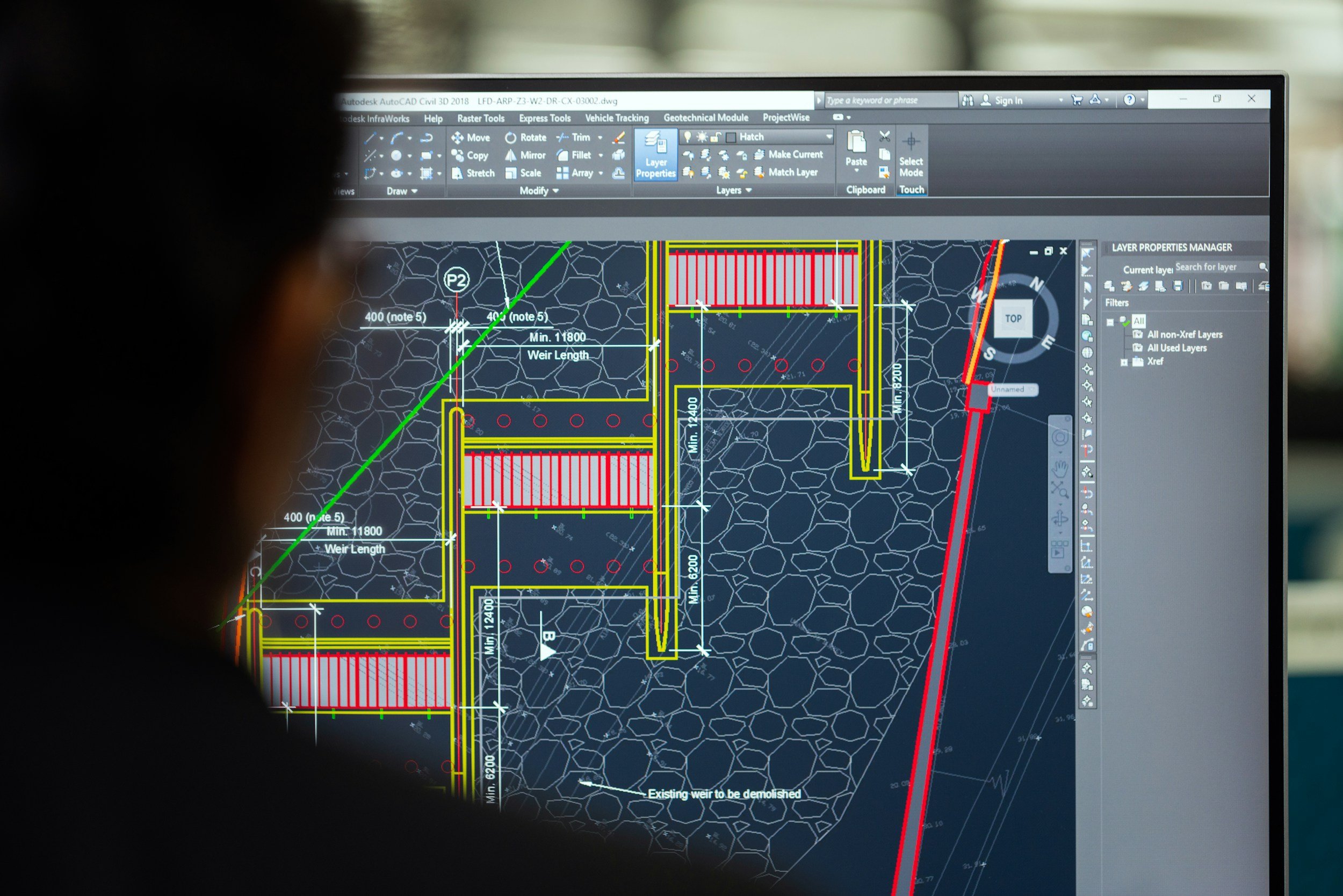

For the CAD drawings, I'll draw up an overview, a layout of where all the connections are on the board. Those connections go to protections, and they'll have specific current ratings. I have to draw it up and then type in all the different protections and which current ratings they need to ensure that they can actually work, that they don't blow a fuse.

You get groups of substations normally. If you're working on that group, it's only one engineer from the customer who's in charge of all of it. They'll want similar things in every single one, so that group is similar, but that group will be completely different from another group. So you're using the same document basically for all four substations in a group because nothing much changes, but it's the small details like the name of the substation, the drawing numbers, what revision it's on. You have to be able to spot those so you're not going back weeks down the line when it's been stopped because something's wrong.

What I enjoy about it

I like that it's something new. I've never really done any design stuff, apart from when I was Year 8 and using CAD to draw a wooden model. I think it's really cool how I'm drawing a substation and then when I go on site, I can see what I've actually designed.

I like using the technology. I've got a really good laptop and I can just draw stuff. I just enjoy it.

And it's opened up opportunities. Siemens has offices in America, which is where I want to move eventually. That gives me hope. I've already been to Berlin for a week for an award ceremony for a project I worked on. I met all the business heads and I was talking to the head of North America, trying to work my way into getting a trip to North Carolina.

What you learn on the job

You need basic electrical knowledge, basically. I did not know a single thing about a substation before I started. I just knew there's transformers, a cable that goes through, and then cables that leave. You get starting documents when you join and then you just learn on the job, and then you do uni at the same time which gets you more knowledge.

Attention to detail is a big one. When you're working on similar projects, you have to spot the small changes. If you miss something and people spot it two weeks down the line, it stops the whole project.

You've got to be good with technology. When I started, I was awful at Excel. I didn't know any of the shortcuts or anything, so it took me a while to get used to that. It's handy to at least have a basic grasp of Excel, PowerPoint, Word, or just software in general. Knowing the shortcuts or having experience with them just makes your job easier.

You need to be able to communicate well with different people. You get messages coming across asking "why is this like this?" and you have to be able to explain it and then have a talk with them. You're working under a mentor who you shadow to understand how they do their job, so you need to be able to communicate with them, with other people in your team, with customers, with different departments.

Being adaptable is probably the best one, being open to learning new things. I did a project in July where I was designing a pilot cable box and it was a lot different from what I'm normally used to. I had no clue about the technology. I had to keep asking people "can you explain how this works? Can you explain how this works so I can draw it?" And I went through about 15 different drawings before I actually got it right. It's just being adaptable to learning new things.

My advice

Research companies and keep an eye on what's happening in the sector. There's always news going out about deals between companies and government, new projects being announced. Follow that stuff because it shows you what's actually happening in the industry.

Don't just wait for opportunities to come to you. Be proactive. Reach out to companies, ask questions, show genuine interest. That makes you stand out from people who just send in an application and hope for the best.

When you get to the interview stage, preparation matters. They want to see you've actually thought about why you want to work for them specifically, not just any engineering company. Know what they do, what projects they're working on, what makes them different.

I'm 19 now and I'm happy where I am. I'm in a good team, getting the chance to learn, getting taught properly. That's worth more than rushing to the next thing. Don't feel like you need to have everything figured out immediately - focus on learning and getting good at what you're doing first.